Pre-Stressing Bar Application in Civil Engineering

| Grade | Yield Strength | Tensile Strength |

| 500 | 500MPa | 630MPa |

| 830 | 830MPa | 1030MPa |

| 930 | 930MPa | 1080MPa |

| 1080 | 1080MPa | 1230MPa |

Stress bars apply a prestressing force to the concrete, which counteracts the tensile stresses that the concrete may experience due to external loads. This pretensioning action helps to keep the concrete in a state of compression, reducing the likelihood of cracking and enhancing the structure’s durability

Our Prestressing thread bar system Grade 930/1080 had been used on several bridges in India,Thailand and Colombia

Tianjin Guotai Gancheng Steel Co., LTD. Main business: fine rolled rebar and supporting anchor (fine rolled nut, fine rolled gasket, fine rolled connector, screw bar), 15.2 steel strand and other steel.

Introduce: Long term supply of Φ15, Φ20, Φ25, Φ28, Φ32, Φ36, Φ40, Φ42, Φ50, Φ63.5, Φ75 (mm) fine rolled screw steel.

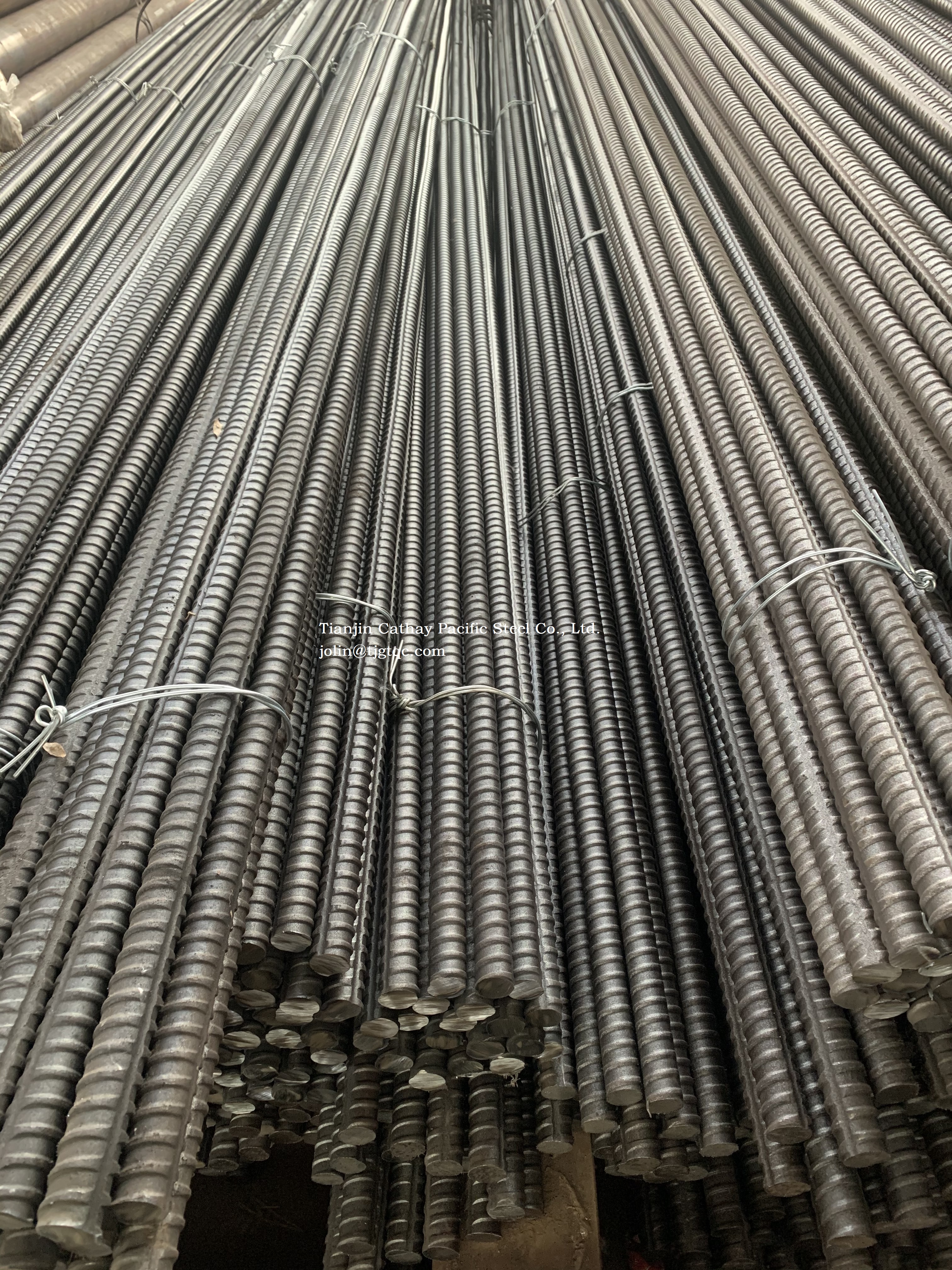

The threaded bar for prestressed concrete (also called fine rolled threaded bar) is a straight bar with large diameter, high strength and high dimensional precision rolled on the whole bar with discontinuous external thread. The steel bar at any section can be screwed on a connector with internal thread for connection or screwed on threaded nuts for anchorage.

Contact Information

Wendy Lee

Tianjin Cathay Pacific Steel Co.,Ltd

Email: tjgtqc@tjgtqc.com

WhatsApp: +86-176 1227 5091

| Nominal Diameter | Diameter | H | B | L | Nominal Section | Nominal Weight | |

| Dv | Dh | ||||||

| mm | mm | mm | mm | mm | mm | mm2 | kg/m |

| 15 | 15 | 15 | 1.0 | 4.5 | 10 | 176 | 1.47 |

| 18 | 18 | 18 | 1.0 | 4.0 | 10 | 254.5 | 2.11 |

| 20 | 20 | 20 | 1.3 | 4.8 | 10 | 314 | 2.47 |

| 25 | 25 | 25 | 1.6 | 6.0 | 12 | 490.9 | 4.10 |

| 32 | 32 | 32 | 2.0 | 7.0 | 16 | 804.2 | 6.65 |

| 36 | 36 | 36 | 2.5 | 8.0 | 18 | 1018 | 8.41 |

| 40 | 40 | 40 | 3.0 | 8.0 | 20 | 1256.6 | 10.34 |

| 50 | 50 | 50 | 3.0 | 9.0 | 24 | 1963.5 | 16.28 |

| 60 | 60 | 60 | 3.0 | 10.0 | 22 | 2827 | 23.26 |

| 63.5 | 63 | 63.5 | 3.0 | 12.0 | 22 | 3167 | 26.20 |

| 65 | 65 | 65 | 3.0 | 12.0 | 22 | 3318 | 27.470 |

| 70 | 70 | 70 | 3.0 | 12.0 | 22 | 3848 | 31.8 |

| 75 | 75 | 75 | 3.0 | 12.0 | 22 | 4418 | 36.9 |

| Grade500/630 | NominalDia. | CrossSection | YieldStrength | TensileStrength | YieldLoad | UltimateLoad | Elongation | NominalWeight |

| mm | mm2 | >=Mpa | >=Mpa | KN | KN | A/% | KG/m | |

| 20 | 314 | 500 | 630 | 157 | 198 | 10 | 2.47 | |

| 25 | 491 | 500 | 630 | 246 | 309 | 10 | 4.1 | |

| 28 | 615 | 500 | 630 | 308 | 387 | 10 | 4.83 |