OEM Factory for Grade 830/1030 25mm Thread Bar - Pre-Stressing Bar – Cathay Detail:

Pre-Stressing Bar

Grade Number of Post Tensioning Tie Bars

| Grade | Yield Strength | Tensile Strength |

| 500 | 500MPa | 630MPa |

| 830 | 830MPa | 1030MPa |

| 930 | 930MPa | 1080MPa |

| 1080 | 1080MPa | 1230MPa |

Application of Post Tensioning System Bar,

Our Prestressing thread bar system Grade 930/1080 had been used on several bridges in India,Thailand and Colombia

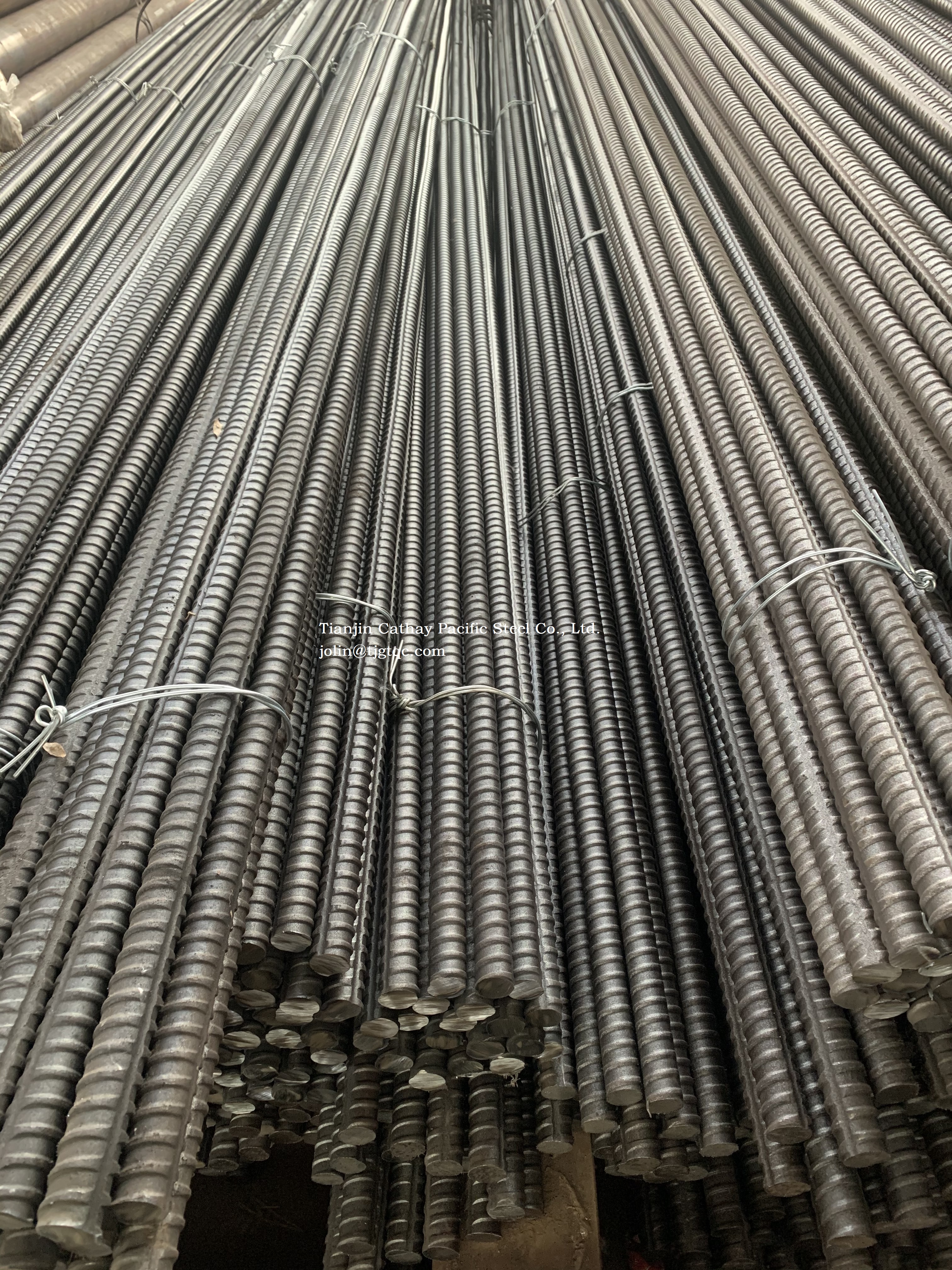

Stock for Post Tensioning Screw Thread Steel Bar

Lead time can be within 7 days.

Tianjin Guotai Gancheng Steel Co., LTD. Main business: fine rolled rebar and supporting anchor (fine rolled nut, fine rolled gasket, fine rolled connector, screw bar), 15.2 steel strand and other steel.

Introduce: Long term supply of Φ15, Φ20, Φ25, Φ28, Φ32, Φ36, Φ40, Φ42, Φ50, Φ63.5, Φ75 (mm) fine rolled screw steel.

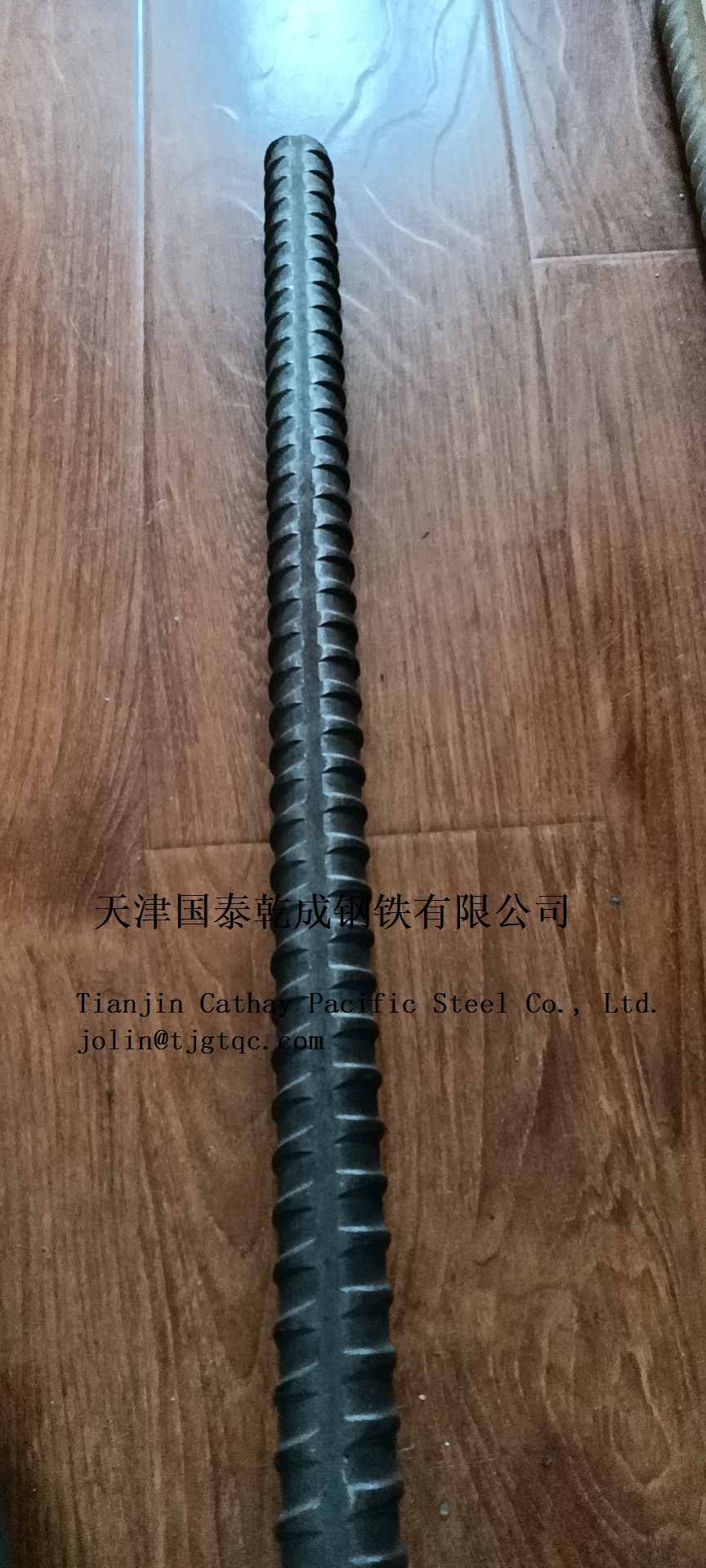

The threaded bar for prestressed concrete (also called fine rolled threaded bar) is a straight bar with large diameter, high strength and high dimensional precision rolled on the whole bar with discontinuous external thread. The steel bar at any section can be screwed on a connector with internal thread for connection or screwed on threaded nuts for anchorage.

Product detail pictures:

Related Product Guide:

"Sincerity, Innovation, Rigorousness, and Efficiency" is the persistent conception of our company for the long-term to develop together with customers for mutual reciprocity and mutual benefit for OEM Factory for Grade 830/1030 25mm Thread Bar - Pre-Stressing Bar – Cathay, The product will supply to all over the world, such as: Haiti, Vietnam, Haiti, Our company upholds the spirit of "innovation, harmony, team work and sharing, trails, pragmatic progress". Give us a chance and we will prove our capability. With your kind help, we believe that we can create a bright future with you together.

| Nominal Diameter | Diameter | H | B | L | Nominal Section | Nominal Weight | |

| Dv | Dh | ||||||

| mm | mm | mm | mm | mm | mm | mm2 | kg/m |

| 15 | 15 | 15 | 1.0 | 4.5 | 10 | 176 | 1.47 |

| 18 | 18 | 18 | 1.0 | 4.0 | 10 | 254.5 | 2.11 |

| 20 | 20 | 20 | 1.3 | 4.8 | 10 | 314 | 2.47 |

| 25 | 25 | 25 | 1.6 | 6.0 | 12 | 490.9 | 4.10 |

| 32 | 32 | 32 | 2.0 | 7.0 | 16 | 804.2 | 6.65 |

| 36 | 36 | 36 | 2.5 | 8.0 | 18 | 1018 | 8.41 |

| 40 | 40 | 40 | 3.0 | 8.0 | 20 | 1256.6 | 10.34 |

| 50 | 50 | 50 | 3.0 | 9.0 | 24 | 1963.5 | 16.28 |

| 60 | 60 | 60 | 3.0 | 10.0 | 22 | 2827 | 23.26 |

| 63.5 | 63 | 63.5 | 3.0 | 12.0 | 22 | 3167 | 26.20 |

| 65 | 65 | 65 | 3.0 | 12.0 | 22 | 3318 | 27.470 |

| 70 | 70 | 70 | 3.0 | 12.0 | 22 | 3848 | 31.8 |

| 75 | 75 | 75 | 3.0 | 12.0 | 22 | 4418 | 36.9 |

| Grade500/630 | NominalDia. | CrossSection | YieldStrength | TensileStrength | YieldLoad | UltimateLoad | Elongation | NominalWeight |

| mm | mm2 | >=Mpa | >=Mpa | KN | KN | A/% | KG/m | |

| 20 | 314 | 500 | 630 | 157 | 198 | 10 | 2.47 | |

| 25 | 491 | 500 | 630 | 246 | 309 | 10 | 4.1 | |

| 28 | 615 | 500 | 630 | 308 | 387 | 10 | 4.83 |

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.

-

Factory wholesale Hex Nut M32 - Bearing Plate ...

-

Factory wholesale Grade 930 Pt Bar/Dia32 Post T...

-

China Gold Supplier for Concrete Reinforced Ste...

-

Good Quality Mining Rock Bolts - Bearing Plate...

-

Hot-selling Grade 930 Pt Bar - Fully Threaded ...

-

Factory Price Post Tensioning Thread Bar - Pre...